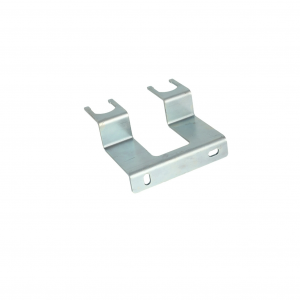

Zigawo Zosindikizidwa za Anodized Aluminium

Kufotokozera

| Mtundu Wazinthu | mankhwala makonda | |||||||||||

| One-Stop Service | Kukula kwa nkhungu ndi kapangidwe-kutumiza zitsanzo-mtanda kupanga-kuyang'ana-pamwamba mankhwala-kuyika-kutumiza. | |||||||||||

| Njira | kupondaponda, kupinda, kujambula mozama, kupanga zitsulo, kuwotcherera, kudula laser etc. | |||||||||||

| Zipangizo | carbon zitsulo, zitsulo zosapanga dzimbiri, aluminiyamu, mkuwa, kanasonkhezereka zitsulo etc. | |||||||||||

| Makulidwe | malinga ndi zojambula za kasitomala kapena zitsanzo. | |||||||||||

| Malizitsani | Utsi utoto, electroplating, otentha-kuviika galvanizing, ❖ kuyanika ufa, electrophoresis, anodizing, blackening, etc. | |||||||||||

| Malo Ofunsira | mbali magalimoto, mbali makina ulimi, mbali makina uinjiniya, mbali zomangamanga zomangamanga, Chalk munda, makina ochezeka zachilengedwe, mbali sitima, mbali ndege, zovekera chitoliro, zida hardware mbali, zidole mbali zamagetsi, etc. | |||||||||||

Mitundu ya masitampu

Timapereka single and multistage, progressive die, deep draw, fourslide, ndi njira zina zopondaponda kuti zitsimikizire njira yabwino kwambiri yopangira zinthu zanu. Akatswiri a Xinzhe atha kufananiza pulojekiti yanu ndi masitampu oyenerera powunikanso chitsanzo chanu cha 3D chomwe mwakweza komanso zojambula zaukadaulo.

- Progressive Die Stamping imagwiritsa ntchito kufa ndi masitepe angapo kuti ipange mbali zozama kuposa momwe zimatheka chifukwa cha kufa kamodzi. Imathandizanso ma geometries angapo pagawo lililonse akamadutsa m'mafa osiyanasiyana. Njirayi ndiyoyenerana bwino ndi kuchuluka kwakukulu komanso magawo akulu monga omwe ali mumakampani amagalimoto. Transfer die stamping ndi njira yofananira, kupatula kupondaponda kopitilira muyeso kumakhudza kachipangizo kachitsulo komwe kamakokedwa panthawi yonseyi. Transfer die stamping imachotsa chogwirira ntchito ndikuchisuntha motsatira cholumikizira.

- Deep Draw Stamping imapanga masitampu okhala ndi mabowo akuya, ngati makona otsekedwa. Njirayi imapanga zidutswa zolimba chifukwa kupindika kwakukulu kwachitsulo kumakakamiza kapangidwe kake kukhala mawonekedwe a crystalline. Kujambula kokhazikika, komwe kumaphatikizapo kufa kosazama komwe kumagwiritsidwa ntchito popanga chitsulo, kumagwiritsidwanso ntchito nthawi zambiri.

- Fourslide Stamping imapanga magawo kuchokera ku nkhwangwa zinayi m'malo mochokera mbali imodzi. Njirayi imagwiritsidwa ntchito popanga tizigawo tating'ono tating'ono kuphatikiza zida zamagetsi monga zolumikizira batire la foni. Kupereka kusinthasintha kwapangidwe, kutsika mtengo wopangira, komanso nthawi yopangira mwachangu, masitampu a fourslide ndi otchuka m'mafakitale apamlengalenga, azachipatala, zamagalimoto, ndi zamagetsi.

- Hydroforming ndi kusintha kwa masitampu. Mapepala amaikidwa pa kufa ndi mawonekedwe apansi, pamene mawonekedwe apamwamba ndi chikhodzodzo cha mafuta omwe amadzaza ndi kuthamanga kwambiri, kukanikiza zitsulo mu mawonekedwe a kufa kwapansi. Magawo angapo amatha kukhala hydroformed nthawi imodzi. Hydroforming ndi njira yachangu komanso yolondola, ngakhale imafunika kudulira kuti mudulire mbalizo papepala pambuyo pake.

- Kutsegula kumadula zidutswa za pepala ngati sitepe yoyamba musanapange. Fineblanking, kusiyanasiyana kopanda kanthu, kumapanga mabala olondola okhala ndi m'mphepete mwake komanso malo athyathyathya.

- Coining ndi mtundu wina wosalemba kanthu womwe umapanga tinthu tating'ono tozungulira. Popeza pamafunika mphamvu yaikulu kupanga kachidutswa kakang'ono, kamene kamaumitsa chitsulocho ndikuchotsa nsonga ndi m'mphepete mwake.

- Kumenya n’kusiyana ndi kubisa kanthu; kumaphatikizapo kuchotsa zinthu pa workpiece m'malo kuchotsa zinthu kupanga workpiece.

- Embossing imapanga mapangidwe atatu-dimensional muzitsulo, mwina atakwezedwa pamwamba kapena kudzera m'madontho angapo.

- Kupinda kumachitika pa axis imodzi ndipo nthawi zambiri amagwiritsidwa ntchito kupanga mbiri mu U, V, kapena L. Njira imeneyi imatheka pomangirira mbali imodzi ndikupinda ina pafa kapena kukanikiza chitsulocho kuti chilowe kapena kutsutsana ndi kufa. Flanging ndi kupindika kwa ma tabo kapena magawo a chogwirira ntchito m'malo mwa gawo lonse.

Kasamalidwe kabwino

Vickers kuuma chida.

Chida choyezera mbiri.

Chida cha Spectrograph.

Zida zitatu zogwirizanitsa.

Chithunzi Chotumiza

Njira Yopanga

01. Kupanga nkhungu

02. Kukonza nkhungu

03. Kukonza waya

04. Chithandizo cha kutentha kwa nkhungu

05. Msonkhano wa nkhungu

06. Kukonza nkhungu

07. Kuwononga ndalama

08. electroplating

09. Kuyesa kwazinthu

10. Phukusi

Njira ya Stamping

Pamwamba mankhwala ndondomeko yazigawo za aluminiyamu stamping:

M'makampani osindikizira, zigawo za aluminiyamu zopondapo ndizofala kwambiri zachitsulo. Njira zodziwika bwino zochizira zitsulo za aluminiyamu ndi izi:

1.Anodizing

Anodizing amatha kupanga bwino chifukwa chosowa kuuma kwapamwamba komanso kuvala kukana kwa zigawo za aluminiyamu zopondapo. Zingathenso kuonjezera kwambiri nthawi yogwiritsira ntchito zigawo za aluminiyamu zopondapo ndikupangitsa kuti mankhwalawa awoneke okongola kwambiri. Masiku ano, anodizing yakhala njira yomwe imagwiritsidwa ntchito kwambiri pazamankhwala a aluminiyamu. Anodizing amatanthauza electrochemical makutidwe ndi okosijeni wa zitsulo kapena aloyi. Aluminiyamu ndi ma aloyi ake amapanga filimu ya okusayidi pazitsulo za aluminiyamu (anode) chifukwa cha mphamvu yamagetsi yomwe imagwiritsidwa ntchito mu electrolyte yogwirizana ndi zochitika zinazake.

2.Kuphulitsa mchenga

Sandblasting nthawi zambiri ndi njira yapakatikati yopangira zida za aluminiyamu zopondapo. Pambuyo pa aluminiyumu stamping zigawo ndi sandblasted, pamwamba burrs ndi madontho mafuta akhoza bwino kuchotsedwa. Ikhoza kupititsa patsogolo ukhondo wamtundu wa aluminiyumu stamping. Poyang'anira zinthu zophulika, malo osiyanasiyana angapezeke ndipo kuuma kwa mankhwala kungathe kuwonjezeka. Kugwira ntchito kwazinthu kungawongoleredwe kwambiri. M'machitidwe opangira chithandizo chamtundu wotsatira, kumamatira pakati pa zigawo za aluminiyamu zopondaponda ndi zokutira zimatha kuonjezedwanso kwambiri, kupangitsa kuti mankhwalawa akhale olimba komanso okongola.

3. Kupukuta mankhwala

Magawo opukutira a aluminiyumu opukutira amatha kukhala pafupi ndi mawonekedwe agalasi, omwe amathandizira kwambiri kalasi ndi kukongola kwazinthu. Komabe, chifukwa cha mawonekedwe a aluminiyumu, masitampu a aluminiyamu amafunikira kupukuta pang'ono. Ngati palibe chithandizo china chapamwamba chomwe chimachitidwa pambuyo pa kupukuta, kukhazikika kwa mankhwalawa kudzakhudzidwa. Kuphatikiza apo, pambuyo popukutidwa ndi zida za aluminiyamu, zimakhala zovuta kusunga mawonekedwe agalasi kwa nthawi yayitali. Choncho, ngati galasi zotsatira chofunika, tikulimbikitsidwa kugwiritsa ntchitochitsulo chosapanga dzimbirimonga zinthu zopangira.

4. Kujambula kwa waya

Pali mitundu yambiri ya masitampu a aluminiyamu, omwe amadziwika kwambiri ndi zojambula zowongoka, zojambula zachisokonezo, zojambula zozungulira komanso zojambula za ulusi. Zigawo zosindikizira za aluminiyamu zitakokedwa ndi waya, zowoneka bwino komanso zowoneka bwino zimawonekera pamwamba, ndipo chopangidwacho chimapatsa anthu mawonekedwe owoneka bwino amitundu yowala ya silika.

Zigawo za aluminiyamu zimafunikira chithandizo chapamwamba pambuyo pokonza, koma njira yochizira imasankhidwa zimatengera zomwe kasitomala akufuna. Popanda pempho lamakasitomala, anodizing nthawi zambiri imakhala yosasinthika.

Chifukwa kusankha Xinzhe kwa mwambo zitsulo stamping mbali?

Xinzhe ndi katswiri wodziwa kupondaponda zitsulo zomwe mumayendera. Kutumikira makasitomala padziko lonse, takhala okhazikika pa zitsulo masitampu pafupifupi khumi. Akatswiri athu opanga nkhungu aluso kwambiri komanso mainjiniya odzipangira okha ndi odzipereka, akatswiri, ndipo ali ndi malingaliro okhwima pantchito.

Kodi chinsinsi cha zomwe takwaniritsa ndi chiyani? Liwu limodzi limapereka chidule cha yankho: chitsimikiziro chaubwino ndi mafotokozedwe. Kwa ife, polojekiti iliyonse ndi yosiyana. Timayendetsedwa ndi masomphenya anu, ndipo ndi ntchito yathu kuti masomphenyawo akwaniritsidwe. Timayesetsa kumvetsetsa gawo lililonse la polojekiti yanu kuti tikwaniritse izi.

Timachita khama kwambiri kuti tikwaniritse masomphenya anu tikawamvetsetsa. Panjira, pali malo angapo oyendera. Izi zimatithandiza kutsimikizira kuti zomalizidwa zimakwaniritsa zosowa zanu.

Gulu lathu pakadali pano likuyang'ana kwambiri zoperekera masitampu azitsulo m'magawo awa:

Kupondaponda m'magawo ang'onoang'ono ndi akulu

Kusindikiza kwachiwiri m'magulu ang'onoang'ono

kugwedeza mkati mwa nkhungu

Kujambula kwa sekondale kapena msonkhano

Machining ndi kupanga

Ngati mukufuna zambiri, musazengereze kulumikizana nafe.